Solutions for Automotive & Metal Fab

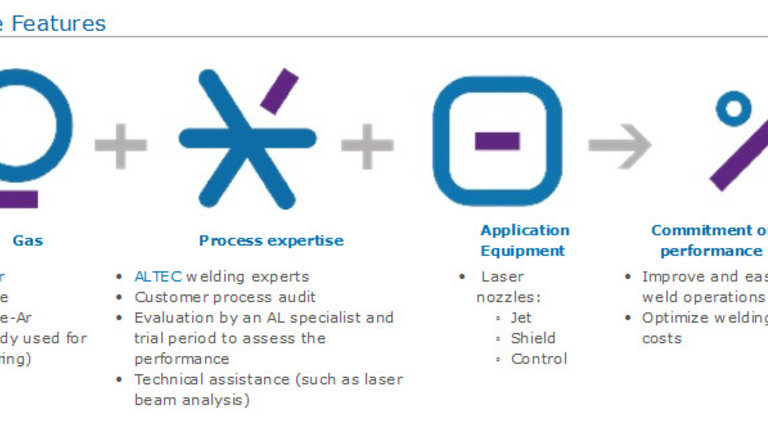

Air Liquide has the know-how to inject and control inert gases and has developed a unique set of proprietary nozzles, each of them adapted to customer’s specific applications. This allows them to facilitate operations, improve quality control, and thus optimize production costs.

As today’s laser welding technology progresses and leads to higher production rates, it is also overcoming key challenges, such as technical and financial limits. Laser power is increasing and technology is becoming easier to handle. Additionally, solid-state technology has become more affordable, and, as automation progresses, CAPEX is simpler to contain.

In addition to the type and power of laser source, weld quality and operations are also influenced by choice of shielding gas and how it is controlled at point of use.

Whatever our customers need to maximize their welding quality and operations, Nexelia for Laser Welding offers the optimal solution